My first homebrew, a summer IPA:

I enjoyed the process, so hey, maybe I’ll keep doing it. This weekend I shared this first batch with friends, bottled a second batch (an ESB), and started fermenting a third (a mostly-rye ale).

I’d decided to keep the equipment and process simple (just one pot and one fermenter, working with local water, etc), at least until I’ve brewed five or ten times and have a better feeling for it. In photos, an amalgamation of the first two batches:

Grains:

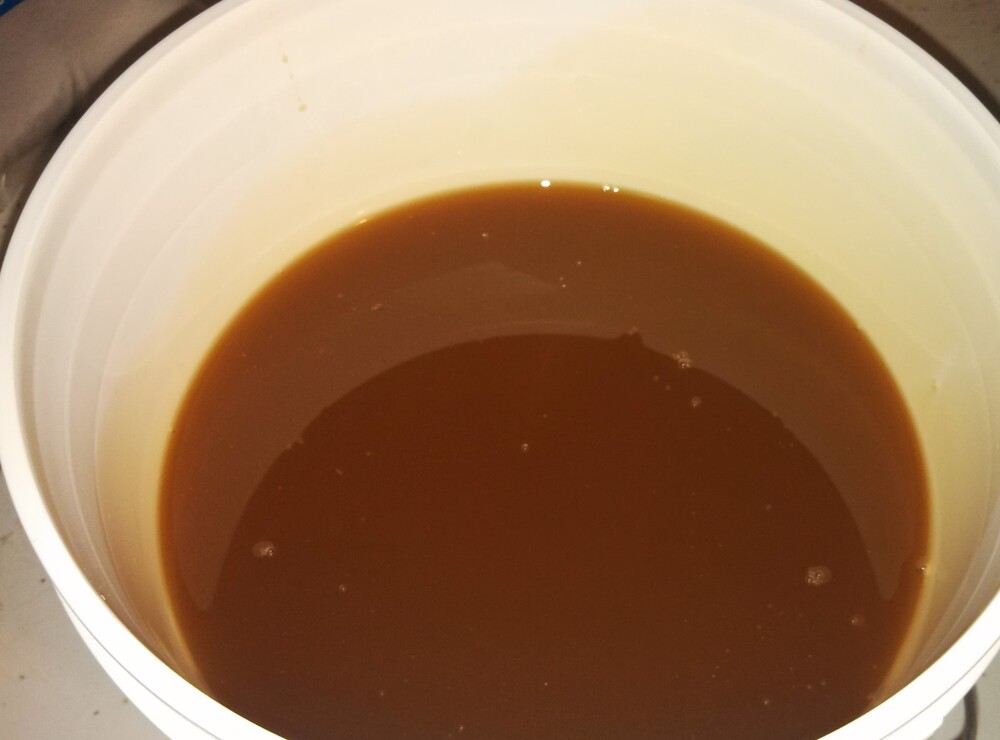

Delicious Hetch Hetchy Reservoir water, straight from the kitchen tap (ignoring mineral/pH tuning for now):

Steeping grains at 150-155F in a pot covered and wrapped with a towel (not only for flavor– this temperature and the use of some diastatic malted barley along with specialty grains should also produce some enzymatic conversion of starches to sugars):

Adding liquid malt (barley) extract to provide the bulk of the fermentable sugars (which also gave me more leeway in the previous step, as I wasn’t depending on the whole grains for a specific amount of sugar), and boiling:

Adding hops at specific intervals during the one hour wort boil (to provide bitterness and flavor and a bit of hop aroma), then chilling the pot of wort in a sink of ice water:

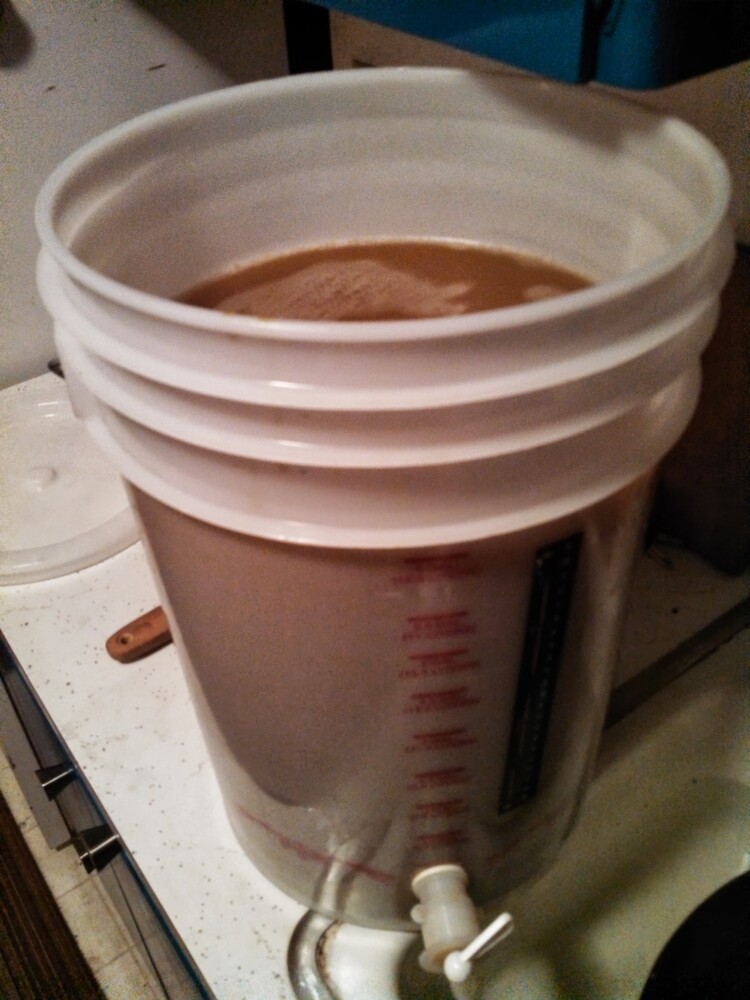

Mixing with fresh water to bring it up to 5 gallons in a simple plastic bucket fermenter, along with dry yeast:

Moved down to the cool garage (about 65F) for a few weeks, to ferment at the low end of the yeast temperature range and ideally produce fewer esters. The bucket’s fitted with an airlock bubbler to let fermentation gases out but prevent contaminants from making their way in:

After about a week, fermentation slowed (determined by taking liquid samples and floating a hydrometer in them to read the specific gravity, which indicates the sugar concentration). I let the yeast keep go for another two weeks to eat other fermentation byproducts and clean up the beer. The staff at the brewing supply store recommend siphoning the beer off the yeast into a secondary fermenter at this point, but most other people I talked to including several experienced homebrewers said this was unnecessary and just another possible source for contamination or oxidation, so I left it in this bucket all three weeks to keep it simple. A week before the end, I tossed in some Simcoe hops to “dry hop” (this adds extra hop aroma, without the bitterness in the taste added by boiling the hops earlier, and Simcoe is a popular dry hop in West Coast beers).

After chilling the entire fermenter in the fridge for three days to “cold crash” the beer (not at all necessary– it just helps the yeast and other solids settle to the bottom, leading to a more clear beer during bottling without using any additives), I bottled and labeled the beer (with a little extra sugar, to give the yeast something to eat once it’s sealed in the bottle to produce carbonation), waited two weeks and then, voila! My first beer.

My goal was just to learn the process (during the first batch I read John Palmer’s excellent How To Brew) , and ideally make a beer that wasn’t terrible– but to my pleasant surprise, I think it’s actually a decent beer I wouldn’t be disappointed to get in a bar. About 6.2% alcohol by volume, a modest amount of grapefruity hop bitterness as intended (I’d been shooting for about 40 IBUs, the low end for an IPA), a touch of sweetness/maltiness in the aftertaste, and the distinctive Simcoe hop aroma. And while it’s varied somewhat bottle to bottle, several of them have poured reasonably clear, with a nice dense head of foam. Success!

Some day I’ll post more specific recipes for this and the science experiment that is beer #2…