I’ve always been a fan of rye as a grain, and wanted to brew a beer where it was taken to extremes. Thus:

became:

Browsing around, I read about Roggenbier, an older rarely-made German beer style made with as much as 50% rye, dating from a time and region where barley was not as plentiful (and according to Wyeast Labs, similar to a dunkelweizen but with rye instead of wheat). Other reading suggested that much of the flavor of rye doesn’t come through in steeping– you really need to mash it (and get enzymes to convert the starches to sugars), though other homebrewers I’ve talked to disagree. In any case, this seemed like a good excuse to make a grain-heavy beer, though still with some malt extract as backup (I’ve promised myself I’ll keep my brewing low-tech, at least until I’ve brewed five times successfully and am sure I’ll keep doing it).

At SF Brewcraft, I browsed the dozens of grain options:

I took as my inspiration this thread on homebrewtalk discussing converting a roggenbier recipe from all-grain to partial mash, and tweaked the recipe to balance the volume I was able to find Munich Liquid Malt Extract in and to make a few other changes.

Grains:

- 2 lbs pilsner malt

- 6.25lbs rye malt (!!)

- 0.75 lbs flaked rye added as last-minute choice (the guy at SF brewcraft said it would help give the beer more head vs. just malted rye)

- 0.5lb caramunich (a medium-dark crystal malt)

- 2oz carafa ii special (a dehusked/debittered chocolate malt: SF Brewcraft has it though the bin is just labeled “carafa”)

- 3.3 lbs Munich Liquid Malt Extract

Hops:(European-style hops that should have a slightly earthy/spicy flavor)

- 1 oz Tettnanger @60

- 1 oz Saaz @15

Yeast:(a larger than usual amount as I expected a bit higher gravity and a challenging fermentation)

- 11g Munich Wheat Beer yeast

- 5g S-04 English Ale Yeast

I followed the usual partial mash procedure, but the 9.5 lbs of dry grains posed some logistical challenges. I’d heated 3 gallons (about 1.25 qts/lb) of water, but I hadn’t reckoned with how porridge-like rye would become when dunked in water – now I understand why people talk about using rice hulls to fluff up a grain bed when using such sticky grains. After the usual 60 minutes of steeping at around 150F, I lifted out the grain bag… and much of the water came out with it, unwilling to release from the grains. If I’d planned ahead I could have poured hotter water over it or used any number of tricks, but this was late in a long day of hanging out with friends, and I didn’t want to spend too much time slaving over the stove, so I let it go and decided to live with the low efficiency and brew it as a lower-alcohol session beer.

After adding the liquid malt extract, doing the hop boil, and so on, I was down from 3 gallons of wort to only 2… I added more make-up water (just bringing it up to 4 gallons to avoid too much dilution), got everything into the fermenter, and I was at an OG of 1.043 : suggesting a 3-4% beer.

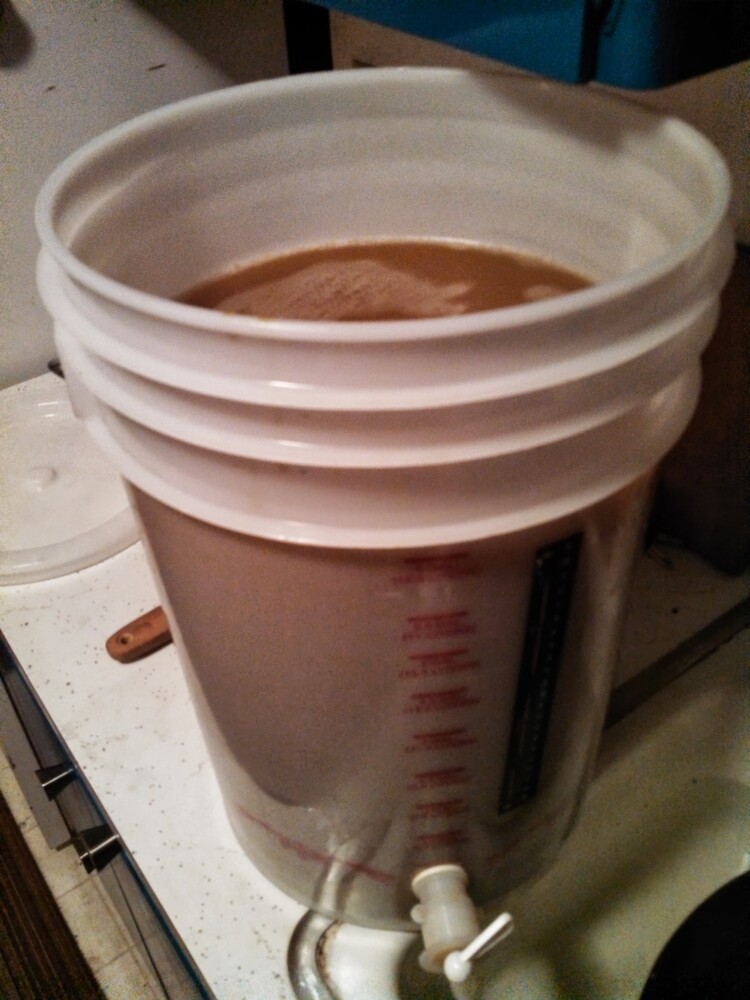

The yeast took off on a nice fermenting kick. I took a few samples over the next few weeks but mostly left it alone for five and a half weeks (it was likely done at around three and a half, but I wanted to synchronize the bottling of this and a later batch on the same later date). It finally stabilized at a well-attenuated SG of 1.011, suggesting an ABV of 3.8%.

Three weeks in, it tasted like slightly bitter straw, or a piece of rye toast with more bitterness than expected. By the time I bottled it, though, it was better– really like a slice of pumpernickel toast (“chewy”), with only a little sweetness. I’m cautiously optimistic…

Bottling and labeling day arrived, and I decided to add 3.6oz of dextrose dissolved in hot water for a light level of carbonation ( 2.5 “volumes of CO2”, as carbonation is traditionally rated, on the high end for an English Ale, but low for most other styles):

The labeling shown earlier took a little extra effort– I photocopied a design onto brown craft paper, but the usual milk paste didn’t stick this porous paper to the glass well– eventually I fell back on rubber cement for some bottles.

Now I just need to be patient for 3-4 weeks…

[edit: 3 weeks later]

I’ve shared a few of these with friends and I’m happy with the result. A small but dense foamy head on the pour. A chewy, distinctly rye, flavorful beer with mild bitterness, light on the alcohol. Good with bread, cheese, and salad, and feels like a solid “at the end of a day of work in the fields” drink. The hop/yeast residue varied– some bottles we opened were a clear dark amber all the way through, others had residual hop and yeast silt at the bottom (probably an artifact of the non-ideal three-hands-full solo bottling, where the siphon kept dipping down into the trub at the bottom of the fermenter).

I declare success.